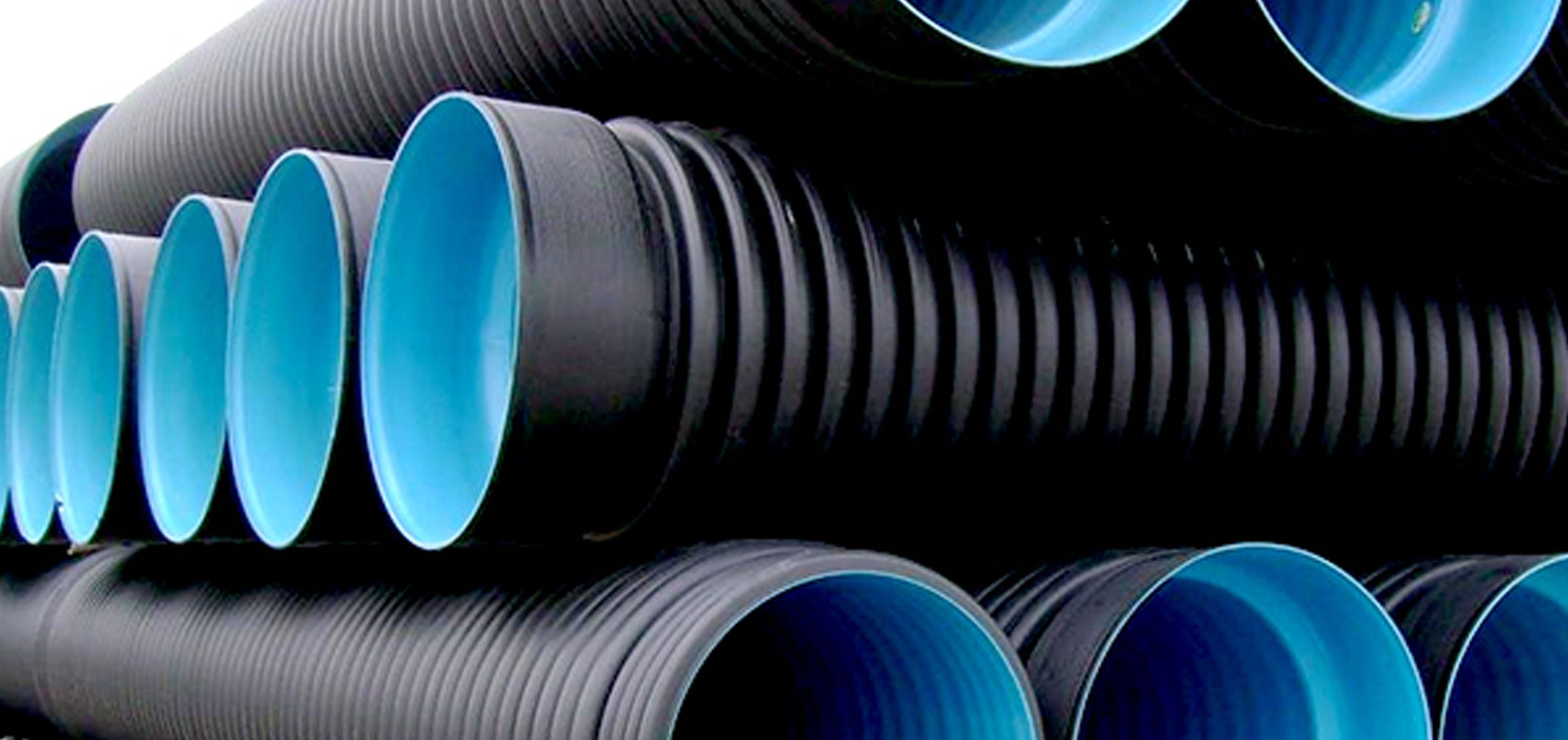

HDPE ob phab ntsa corrugated yeeb nkab raw khoom

HDPE ob phab ntsa corrugated yeeb nkab raw khoom,

HDPE rau ob phab ntsa corrugated yeeb nkab ntau lawm, Dab tsi ntawm HDPE resin yog siv rau ob phab ntsa corrugated yeeb nkab,

HDPE ob phab ntsa corrugated yeeb nkab raw khoom

1. Cov khoom siv raw: Cov khoom siv raw ntawm PE ob-phab ntsa hauv qab feem ntau yog tsim los ntawm polyethylene, txhim kho cov khoom siv thiab cov xim.Yog tias cov khoom siv raw ntub, txhawm rau txhim kho kev tsim khoom, tsim nyog defoamer tuaj yeem ntxiv.

2, kev ua tau zoo ntawm cov khoom siv raw: yuav ua li cas los tsim tus nqi qis, cov khoom siv zoo, feem ntau nyob ntawm kev xaiv cov khoom siv raw thiab cov qauv sib xyaw.

Cov kev cai dav dav rau kev ua tau zoo ntawm polyethylene (PE) suav nrog melt flow rate (MFR), oxidation induction time (OIT) thiab ceev.Qhov luaj li cas ntawm cov dej ntws tau qhia txog qhov loj ntawm molecular hnyav.Feem ntau hais lus, cov khoom siv nrog cov dej ntws ntau dua yog qhov tsim nyog rau kev ua thiab kev tsim, thiab tuaj yeem txhim kho qhov zoo

ntau lawm efficiency.Txawm li cas los xij, nws tsis tuaj yeem loj dhau, uas muaj kev cuam tshuam ntau dua ntawm lub nplhaib nruj.Nws yog tsim nyog los xaiv ntawm 0.8-1.5g / 10min (190 ℃, 5kg).Oxidation induction lub sij hawm txiav txim siab lub sij hawm ntawm oxidation puas.Rau lub tshuab nqus tsev uas xav tau 50 xyoo ntawm kev siv, kev tswj cov oxidation induction lub sij hawm ntawm raw cov ntaub ntawv yog tus yuam sij los xyuas kom meej lub neej kev pab cuam ntawm 50 xyoo.Nws tau hais meej meej nyob rau hauv GB / T19472.1-2004 tias lub sijhawm oxidation induction ntawm cov khoom siv raw yuav tsum yog ≥20min (200 ℃).Rau nruab nrab thiab siab ceev polyethylene, nws cov khoom tuaj yeem hloov kho los ntawm kev hloov qhov ceev.Vim peb paub tias qhov ntom ntom polyethylene tuaj yeem ua rau nws lub sijhawm ua haujlwm tsis zoo.

ntau lawm efficiency.Txawm li cas los xij, nws tsis tuaj yeem loj dhau, uas muaj kev cuam tshuam ntau dua ntawm lub nplhaib nruj.Nws yog tsim nyog los xaiv ntawm 0.8-1.5g / 10min (190 ℃, 5kg).Oxidation induction lub sij hawm txiav txim siab lub sij hawm ntawm oxidation puas.Rau lub tshuab nqus tsev uas xav tau 50 xyoo ntawm kev siv, kev tswj cov oxidation induction lub sij hawm ntawm raw cov ntaub ntawv yog tus yuam sij los xyuas kom meej lub neej kev pab cuam ntawm 50 xyoo.Nws tau hais meej meej nyob rau hauv GB / T19472.1-2004 tias lub sijhawm oxidation induction ntawm cov khoom siv raw yuav tsum yog ≥20min (200 ℃).Rau nruab nrab thiab siab ceev polyethylene, nws cov khoom tuaj yeem hloov kho los ntawm kev hloov qhov ceev.Vim peb paub tias qhov ntom ntom polyethylene tuaj yeem ua rau nws lub sijhawm ua haujlwm tsis zoo.

HDPE yeeb nkab qib muaj dav lossis bimodal faib ntawm molecular hnyav.Nws muaj zog creep kuj thiab zoo sib npaug ntawm rigidity thiab toughness.Nws yog ruaj heev thiab muaj tsawg sag thaum ua tiav.Cov kav dej uas tsim los ntawm cov khoom siv no muaj lub zog zoo, rigidity thiab kev cuam tshuam tsis zoo thiab cov cuab yeej zoo ntawm SCG thiab RCP.

Cov resin yuav tsum tau muab khaws cia rau hauv ib qho chaw qhuav, qhuav warehouse thiab deb ntawm hluav taws thiab tshav ntuj ncaj qha.Nws yuav tsum tsis txhob muab tso rau hauv qhov qhib cua.Thaum lub sij hawm kev thauj mus los, cov khoom yuav tsum tsis txhob raug tshav ntuj los yog nag thiab yuav tsum tsis txhob raug thauj nrog xuab zeb, av, seem hlau, thee lossis iav.Kev thauj mus los ua ke nrog cov tshuaj lom, corrosive thiab flammable yog nruj me ntsis txwv.

Daim ntawv thov

HDPE yeeb nkab qib tuaj yeem siv rau hauv kev tsim cov kav dej siab, xws li cov kav dej siab, cov kav dej roj thiab lwm cov kav dej.Nws kuj tseem siv tau los ua cov kav dej tsis muaj zog xws li ob-phab ntsa corrugated kav, hollow-wall winding kav, silicon-core kav, kav dej ua liaj ua teb thiab aluminiumplastics compound pipes.Tsis tas li ntawd, los ntawm reactive extrusion (silane cross-linking), nws tuaj yeem siv los ua cov kav dej sib txuas polyethylene (PEX) rau kev muab dej txias thiab dej kub.