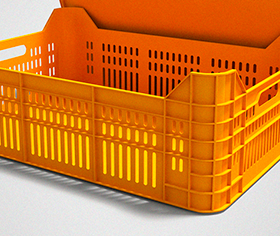

HDPE Txhaj molding rau crate

HDPE Txhaj molding rau crate,

HDPE rau Crate, HDPE txhaj tshuaj molding,

Yas crate tsim los ntawm high density polyethylene (HDPE) txhaj tshuaj molding ntawm thawj fusion.

Crate yog molded nrog cov khoom tshwj xeeb HDPE kom ua tau zoo heev.Lub melting ceev ntawm cov khoom tshwj xeeb yog 3.6-4.5 g / 10 feeb, qhov nro yog tshaj 25 Pa, lub zog tensile tshaj 60% thiab lub contraction quab yuam yog tshaj 40 Pa. Feem ntau HDPE cov khoom muaj me ntsis branching, tab sis cov khoom tshiab tshwj xeeb siv rau crates muab nws muaj zog intermolecular rog thiab tensile zog tshaj LDPE.Nws qhov saum npoo yog qhov nyuaj dua thiab pob tshab, thiab nws tuaj yeem tiv taus qhov kub thiab txias (120 C / 248 F rau lub sijhawm luv, 110 C / 230 F tsis tu ncua), txhawm rau kom ncav cuag qhov yuav tsum tau ua kom ntev.Nws yuav tsum raug sau tseg tias HDPE, tsis zoo li polypropylene, tsis tuaj yeem tiv taus qhov siab dav dav.

Txhaj Molding

Txhaj tshuaj molding yog ib txoj kev tsim cov yas uas koom nrog kev txhaj tshuaj molten yas raw cov ntaub ntawv mus rau hauv lub kaw chamber los yog pwm.Cov txheej txheem no muaj peb yam tseem ceeb:

Sib tsoo thiab cua sov cov yas kom txog thaum nws ntws hauv siab.

Txhaj cov yas hauv pwm thiab cia nws txias.

Qhib cov pwm kom tshem tawm lub thawv yas.

Ib tug reciprocating ntsia hlau hom extruder yog siv nyob rau hauv kev lag luam rau yas ua rau sib tov;muaj rov sib tov thiab kneading ntawm cov ntsia hlau hom extruder.Thaum cov yas (cov khoom siv raw) npaj tau txhaj, raws li cov ntsia hlau txav, nws thawb cov yas tawm ntawm extruder thiab mus rau hauv pwm.

Ua kom cov duab xav tau los ntawm cov neeg siv khoom, muaj cov pwm tsim nrog tshwj xeeb uas muaj cov duab zoo.Feem ntau nws muaj ob feem lossis ib nrab nrog cov yam ntxwv zoo sib xws.Ib qho muaj peev xwm txav los yog nws tseem nyob thaum lwm qhov ntawm cov pwm tuaj yeem txav mus los.Tom qab molding, lwm tus ib nrab tuaj yeem txav tau yog li tso cov khoom los ntawm cov pwm hauv daim ntawv tsis muaj kev cuam tshuam.Cov pwm muaj ob peb lossis ntau qhov qhib lossis cov channel.Cov no yog siv los qhia cov yas rau hauv pwm, tso cua, thiab tso cai rau qee cov yas ntws tawm ntawm pwm.

Txhaj tshuaj molding tau txwv ntau lawm thaum nws los txog rau kev tsim khoom ntawm ib sab ntim los yog crates.Tubs, pails, khob, ntim khoom noj, thiab tais yog piv txwv.Los ntawm nws tus kheej, kev txhaj tshuaj molding tsis haum rau kev tsim cov khoom kaw, hollow cov khoom xws li lub raj mis yas uas yog vim li cas nws thiaj li tsim nyog rau kev tsim cov khoom qhib.Txhawm rau tsim cov khoom no, ib qho roj inert yog siv.Qhov no yog siv vim nws yuav tshem tawm cov tshuaj tiv thaiv uas tuaj yeem tshwm sim hauv pwm thaum cov txheej txheem nyob rau hauv cov lus tsa suab.Qhov no yog nkag mus rau hauv cov pwm ib nrab ntim nrog molten yas.Qhov no thawb cov yas mus rau saum npoo ntawm cov pwm ua ib qho hollow.Cov txheej txheem no hu ua gas-assisted txhaj molding.

Daim ntawv thov

HDPE txhaj- molding qib yog siv los ua cov ntim khoom siv rov siv dua, xws li cov thawv npias, cov dej haus, cov khoom noj, cov zaub zaub thiab cov qe qe thiab tseem tuaj yeem siv los ua cov tais yas, cov thawv ntim khoom, cov khoom siv hauv tsev, cov khoom siv niaj hnub thiab nyias- phab ntsa ntim khoom noj.Nws tseem tuaj yeem siv rau hauv kev tsim cov khoom siv-siv thoob, khib nyiab khib nyiab thiab cov khoom ua si.Los ntawm cov txheej txheem extrusion thiab compression molding thiab txhaj tshuaj molding, nws tuaj yeem siv los tsim lub kaus mom ntawm cov dej huv, dej ntxhia, dej tshuaj yej thiab kua txiv hmab txiv ntoo.