PVC cob rau flooring

PVC cob rau flooring,

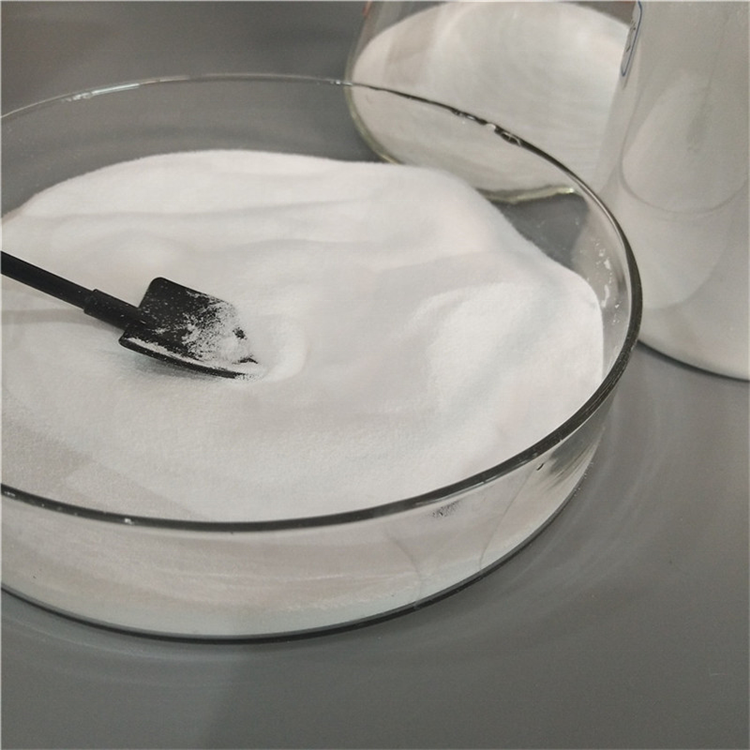

PVC pem teb raw khoom, PVC cob rau flooring,

Pressed flooring muaj li ntawm anti-static PVC daim hlau

Cov khoom siv los tsim PVC pem teb suav nrog:

(a) polyvinyl chloride;

(b) ib tug plasticizer nyob rau hauv ib tug npaum li ntawm 5-35 qhov chaw los ntawm qhov hnyav ib 100 qhov chaw los ntawm qhov hnyav ntawm polyvinyl chloride;

thiab

(c) luv iav fibers muaj ib txoj kab uas hla ntawm 6-12 µm thiab qhov nruab nrab ntev ntawm 2-12 mm nyob rau hauv ib tug npaum li cas ntawm 0.5-30 qhov chaw los ntawm qhov hnyav ib 100 qhov chaw los ntawm qhov hnyav ntawm polyvinyl chloride;

calendering lub compound rau hauv ib daim ntawv resin nrog calender yob;thiab nyob ua ke,

embossing nto ntawm daim ntawv resin los ntawm kev siv lub tshuab embossing muaj li ntawm embossing yob thiab ib tug thaub qab yob nrog ib tug ratio ntawm peripheral tshaj tawm ntawm embossing yob 1 mus rau lub peripheral tshaj tawm ntawm lub kawg yob ntawm lub calender yob nyob rau hauv ntau yam. ntawm 1.3-2.3.

PVC flooring muaj cov yam ntxwv thiab qhov zoo hauv qab no:

Anti-Bacterial

Antistatic

Acoustic rwb thaiv tsev

Resistant rau feem ntau cov neeg ua hauj lwm tshuaj diluted nrog acids, bases, roj thiab fuels

Smooth matte nyhuv

Solvent-dawb

Ultra-compact nto zoo tagnrho rau tu thiab huv si

PU nto tiav (tsis muaj wax - tsis muaj polish)

Muaj nyob rau hauv 19 xim sib txawv

Nta

PVC yog ib qho ntawm cov khoom siv thermoplastic feem ntau siv.Nws tuaj yeem siv los ua cov khoom lag luam nrog lub siab tawv thiab lub zog, xws li cov kav dej thiab fittings, profiled qhov rooj, qhov rais thiab cov ntawv ntim.Nws tseem tuaj yeem ua cov khoom muag muag, xws li cov yeeb yaj kiab, cov ntawv txheeb, cov xaim hluav taws xob thiab cov cables, cov ntaub pua tsev thiab cov tawv hluavtaws, los ntawm kev ntxiv cov yas yas

Tsis muaj

| Qib | QS-650 | S-700 Nws | S-800 Nws | S-1000 Nws | QS-800F | QS-1000F | QS-1050 P | |

| Nruab nrab polymerization degree | 600-700 Nws | 650-750 | 750-850 : kuv | 970-1070 Ib | 600-700 Nws | 950-1050 : kuv | 1000-1100 Nws | |

| Pom tseeb qhov ceev, g / ml | 0.53-0.60 Nws | 0.52-0.62 Nws | 0.53-0.61 Nws | 0.48-0.58 Nws | 0.53-0.60 Nws | ≥0.49 | 0.51-0.57 Nws | |

| Volatiles cov ntsiab lus (dej suav nrog), %, ≤ | 0.4 | 0.30 Nws | 0.20 ib | 0.30 Nws | 0.40 Nws | 0.3 | 0.3 | |

| Plasticizer nqus ntawm 100g resin, g, ≥ | 15 | 14 | 16 | 20 | 15 | 24 | 21 | |

| VCM residual, mg/kg ≤ | 5 | 5 | 3 | 5 | 5 | 5 | 5 | |

| Kev tshuaj ntsuam % | 0.025 hli mesh% ≤ | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 0.063m mesh % ≥ | 95 | 95 | 95 | 95 | 95 | 95 | 95 | |

| Ntses qhov muag naj npawb, No./400cm2, ≤ | 30 | 30 | 20 | 20 | 30 | 20 | 20 | |

| Tus naj npawb ntawm impurity hais, No., ≤ | 20 | 20 | 16 | 16 | 20 | 16 | 16 | |

| Dawb (160ºC, 10 feeb tom qab), %, ≥ | 78 | 75 | 75 | 78 | 78 | 80 | 80 | |

| Daim ntawv thov | Txhaj Moulding Materials, Cov Khoom Siv Yeeb Nkab, Cov Khoom Siv Calendering, Rigid Foaming Profiles, Lub Tsev Sheet Extrusion Rigid Profile | Ib nrab-rigid Sheet, Phaj, Pem Teb Khoom, Linning Epidural, Cov Khoom Siv Hluav Taws Xob, Cov Khoom Siv Tsheb | Pob tshab zaj duab xis, ntim, duab los qhia, txee thiab hauv pem teb, khoom ua si, lub raj mis thiab ntim | Cov ntawv, tawv tawv, cov khoom siv yeeb nkab, Profiles, Bellows, Cable Protective Pipes, Ntim Zaj duab xis | Cov khoom siv Extrusion, Hluav Taws Xob, Cov Khoom Siv Hluav Taws Xob, Cov Khoom Siv Hluav Taws Xob thiab cov phaj | Cov ntawv, Calendering Materials, Pipes Calendering Tools, Insulating Materials ntawm Hlau thiab Cables | Cov kav dej, cov kav dej haus, cov kav dej ua npuas dej, cov kav dej kav dej, cov kav hlau, cov kav dej tsis zoo | |