PVC cob rau ntoo yas extrusion

PVC cob rau ntoo yas extrusion,

PVC CIF Is Nrias teb, PVC K67, PVC cob rau extrusion,

Khoom nthuav dav

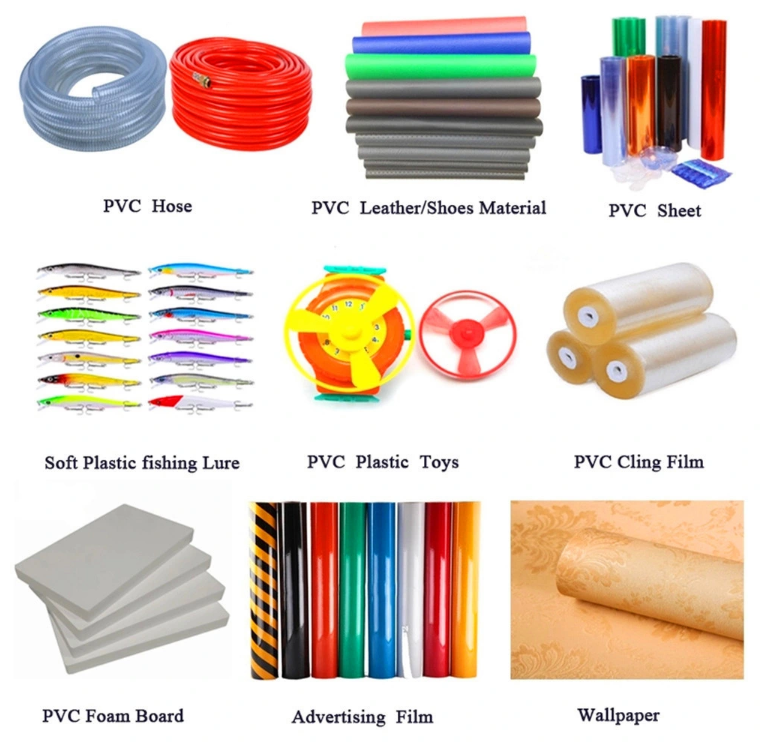

PVC yog lub ntsiab lus rau polyvinyl chloride.Resin yog ib yam khoom siv feem ntau siv hauv kev tsim cov yas thiab roj hmab.PVC resin yog cov hmoov dawb feem ntau siv los tsim cov thermoplastics.Nws yog cov khoom siv hluavtaws dav siv hauv ntiaj teb niaj hnub no.Polyvinyl chloride resin muaj cov yam ntxwv zoo xws li cov khoom siv ntau, kev tsim khoom siv technology, tus nqi qis, thiab ntau yam kev siv.Nws yog ib qho yooj yim rau txheej txheem thiab tuaj yeem ua tiav los ntawm molding, laminating, txhaj tshuaj molding, extrusion, calendering, tshuab moulding thiab lwm yam.Nrog rau lub cev zoo thiab cov khoom siv tshuaj lom neeg, nws yog dav siv hauv kev lag luam, kev tsim kho, kev ua liaj ua teb, lub neej txhua hnub, ntim khoom, hluav taws xob, kev siv hluav taws xob, thiab lwm yam.PVC resins feem ntau muaj tshuaj tiv thaiv siab.Nws muaj zog heev thiab tiv taus dej thiab puas.Polyvinyl chloride resin (PVC) tuaj yeem ua tiav rau hauv ntau yam khoom yas.PVC yog lub teeb yuag, pheej yig, thiab ib puag ncig tus phooj ywg plastics.

Nta

PVC yog ib qho ntawm cov khoom siv thermoplastic feem ntau siv.Nws tuaj yeem siv los ua cov khoom lag luam nrog lub siab tawv thiab lub zog, xws li cov kav dej thiab fittings, profiled qhov rooj, qhov rais thiab cov ntawv ntim.Nws tseem tuaj yeem ua cov khoom muag muag, xws li cov yeeb yaj kiab, cov ntawv txheeb, cov xaim hluav taws xob thiab cov cables, cov ntaub pua tsev thiab cov tawv hluavtaws, los ntawm kev ntxiv cov yas yas

Tsis muaj

| Qib | QS-650 | S-700 Nws | S-800 Nws | S-1000 Nws | QS-800F | QS-1000F | QS-1050 P | |

| Nruab nrab polymerization degree | 600-700 Nws | 650-750 | 750-850 : kuv | 970-1070 Ib | 600-700 Nws | 950-1050 : kuv | 1000-1100 Nws | |

| Pom tseeb qhov ceev, g / ml | 0.53-0.60 Nws | 0.52-0.62 Nws | 0.53-0.61 Nws | 0.48-0.58 Nws | 0.53-0.60 Nws | ≥0.49 | 0.51-0.57 Nws | |

| Volatiles cov ntsiab lus (dej suav nrog), %, ≤ | 0.4 | 0.30 Nws | 0.20 ib | 0.30 Nws | 0.40 Nws | 0.3 | 0.3 | |

| Plasticizer nqus ntawm 100g resin, g, ≥ | 15 | 14 | 16 | 20 | 15 | 24 | 21 | |

| VCM residual, mg/kg ≤ | 5 | 5 | 3 | 5 | 5 | 5 | 5 | |

| Kev tshuaj ntsuam % | 0.025 hli mesh% ≤ | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 0.063m mesh % ≥ | 95 | 95 | 95 | 95 | 95 | 95 | 95 | |

| Ntses qhov muag naj npawb, No./400cm2, ≤ | 30 | 30 | 20 | 20 | 30 | 20 | 20 | |

| Tus naj npawb ntawm impurity hais, No., ≤ | 20 | 20 | 16 | 16 | 20 | 16 | 16 | |

| Dawb (160ºC, 10 feeb tom qab), %, ≥ | 78 | 75 | 75 | 78 | 78 | 80 | 80 | |

| Daim ntawv thov | Txhaj Moulding Materials, Cov Khoom Siv Yeeb Nkab, Cov Khoom Siv Calendering, Rigid Foaming Profiles, Lub Tsev Sheet Extrusion Rigid Profile | Ib nrab-rigid Sheet, Phaj, Pem Teb Khoom, Linning Epidural, Cov Khoom Siv Hluav Taws Xob, Cov Khoom Siv Tsheb | Pob tshab zaj duab xis, ntim, duab los qhia, txee thiab hauv pem teb, khoom ua si, lub raj mis thiab ntim | Cov ntawv, tawv tawv, cov khoom siv yeeb nkab, Profiles, Bellows, Cable Protective Pipes, Ntim Zaj duab xis | Cov khoom siv Extrusion, Hluav Taws Xob, Cov Khoom Siv Hluav Taws Xob, Cov Khoom Siv Hluav Taws Xob thiab cov phaj | Cov ntawv, Calendering Materials, Pipes Calendering Tools, Insulating Materials ntawm Hlau thiab Cables | Cov kav dej, cov kav dej haus, cov kav dej ua npuas dej, cov kav dej kav dej, cov kav hlau, cov kav dej tsis zoo | |

Daim ntawv thov

Ntim

(1) Ntim: 25kg net / pp hnab, lossis kraft ntawv hnab.

(2) Chaw thau khoom kom muaj nuj nqis: 680Bags / 20'container, 17MT / 20'container.

(3) Chaw thau khoom kom muaj nuj nqis: 1000Bags / 40'container, 25MT / 40'container .Formulation kev txiav txim

Formula tsim yog raws li cov khoom ua tau zoo, cov khoom siv raw thiab cov khoom siv, cov txheej txheem molding thiab cov khoom siv.Qhov no yog ib qho nyuaj thiab tedious ua hauj lwm, thiaj li yuav muaj kev nyab xeeb, feem ntau tsuas yog nyob rau hauv lub hauv paus ntawm tus thawj mature formula raws li kev paub ntawm me me kev hloov kho, thiab tom qab ntawd los ntawm kev sim los txiav txim siab qhov kev daws teeb meem zoo tshaj plaws uas ua tau raws li qhov yuav tsum tau ua.Tus sau yog ua raws li cov qauv ntawm PVC qhov rooj thiab qhov rais profiles, ntxiv ntoo hmoov, foaming agent, foaming agent, colouring agent, thiab tom qab ntawd raws li kev xeem orthogonal. los txiav txim seb tus nqi ntawm cov khoom nyoos thiab cov khoom siv sib txawv.

Qhov sib ntxiv ntawm cov hmoov ntoo feem ntau yuav ua rau cov khoom ntws ntawm cov khoom tsis zoo. Nrog rau qhov nce ntawm cov ntsiab lus ntawm cov hmoov ntoo, lub sij hawm plasticizing txuas ntxiv, thiab cov fluidity yuav qis dua thiab qis dua.Yog tias qhov fluidity ntawm cov khoom tsis zoo heev. , ntoo hmoov yuav raug ntau dua shear quab yuam, nce lub sij hawm nyob rau hauv lub extruder, kom cov hmoov ntoo yog yooj yim mus hlawv, tsis conducive rau extrusion; Piv txwv li, yog hais tias lub liquidity loj dhau los tsim txaus extrusion siab, nws tseem yuav ua rau lub zog tsis xws luag thiab nto defects ntawm cov khoom.Yog li ntawd, nyob rau hauv cov txheej txheem extrusion, cov khoom rheological ntawm lub cev muaj kev cuam tshuam zoo rau cov txheej txheem machining thiab cov khoom ntawm cov khoom kawg.Table 2 qhia txog kev ua cov khoom ntawm cov khoom sib txawv. ntoo zaub mov.

Vim qhov loj me me thiab qhov ntom ntom me me ntawm cov hmoov ntoo siv hauv kev sim, qhov ntim piv ntawm cov hmoov ntoo muab tub lim hauv qhov system nce nrog qhov nce ntawm cov nyiaj filling, thiab lub peev xwm adsorption ntawm lubricant, plasticizer thiab ua additives. yog qhov loj.Txawm hais tias cov txheej txheem ua tau tuaj yeem ua kom muaj kev sib txhuam loj loj kom ceev cov plasticizer, tab sis tsis txaus rau offset vim plasticizer, ua additives thiab lwm yam adsorbed plasticizer ceev kom qeeb qhov cuam tshuam ntawm plasticizer lub sij hawm, kom lub plasticizer ncua. loj dua cov ntsiab lus ntawm ntoo hmoov, ntau ua AIDS absorbed, uas yuav ua rau kom lub plasticizing lub sij hawm, lub pluag kev ua tau zoo.Qhov kawg kev txiav txim ntawm kev xaiv ntoo hmoov ntsiab lus ntawm 30.

Lwm cov ntaub ntawv raw siv yog 100 feem PVC, 3 qhov chaw tribasic lead sulfate, 1.5 qhov chaw dibasic lead sulfate, 0.5 qhov chaw lead stearate, 0.4 qhov chaw calcium stearate, 0.8 qhov chaw stearate, polyethylene wax..3 PCS, acrylic txias copolymer 5 PCS, chlorinated polyethylene 6 PCS, CaCO30 PCS, AC foaming agent 0.9 PCS, ACR-530 5 PCS, hlau daj 0.31 PCS, hlau xim av 0.15 PCS.