PVC yog tsim los ntawm vinyl chloride los ntawm dawb radical polymerization.Los ntawm kev ncua polymerization, emulsion polymerization thiab bulk polymerization, ncua kev kawm ntawv polymerization yog txoj kev tseem ceeb, suav txog li 80% ntawm tag nrho cov khoom siv PVC.Hauv kev lag luam, PVC txheej txheem ntau lawm feem ntau yog raws li txoj hauv kev tau txais cov yas chloride monomer kom paub qhov txawv, tuaj yeem muab faib ua calcium carbide method, ethylene method thiab imported (EDC, VCM) monomer method (tseem hu ua ethylene method thiab imported monomer method) .Raws li cov txheej txheem ntau lawm, PVC hmoov muab faib ua: universal PVC resin, PVC resin nrog high degree ntawm polymerization, crosslinking PVC cob.Universal PVC cob yog tsim los ntawm polymerization ntawm vinyl chloride monomer nyob rau hauv qhov kev txiav txim ntawm pib;PVC resin nrog qib siab ntawm polymerization yog hais txog cov resin tsim los ntawm kev ntxiv cov saw nce tus neeg sawv cev hauv cov txheej txheem polymerization ntawm vinyl chloride monomer;Crosslinked PVC resin yog ib qho resin uas yog polymerized los ntawm kev ntxiv crosslinking tus neeg sawv cev uas muaj diene thiab polyene nyob rau hauv lub polymerization system ntawm vinyl chloride monomer.

Suspension polyvinyl chloride resin tam sim no qauv:

Sg-1: K 77-75 nruab nrab degree ntawm polymerization

Sg-2: K 74-73 nruab nrab degree ntawm polymerization

Sg-3: K tus nqi 72-71 Nruab nrab polymerization degree 1350-1250

Sg-4: K tus nqi 70-69 nruab nrab degree ntawm polymerization 1250-1150

Sg-5: K tus nqi 68-66 Nruab nrab degree ntawm polymerization 1100-1000

Sg-6: K tus nqi 65-63 Nruab nrab degree ntawm polymerization 950-850

Sg-7: K tus nqi 62-60 nruab nrab degree ntawm polymerization 850-750

Sg-8: K tus nqi 59-55 nruab nrab degree ntawm polymerization 750-650

Cov ntawv thov tseem ceeb:

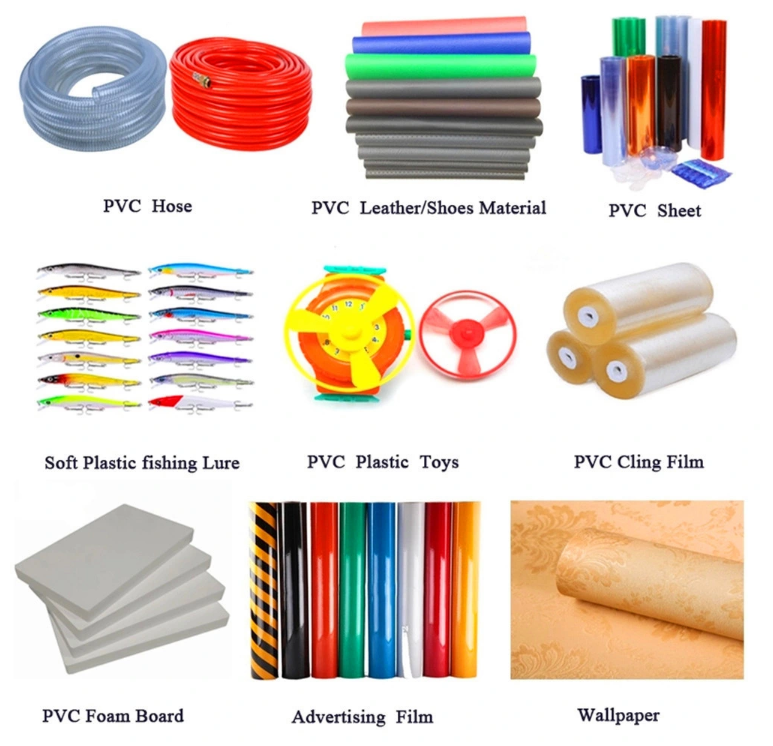

PVC resin tuaj yeem ua tiav rau hauv ntau yam khoom yas, raws li nws siv tau muab faib ua ob pawg ntawm cov khoom muag muag thiab tawv, feem ntau yog siv rau hauv kev tsim cov pob tshab, cov yeeb nkab fittings, cov ntawv kub, cov khoom siv ntshav, mos thiab tawv. cov kav dej, daim hlau, qhov rooj thiab qhov rais, profiles, zaj duab xis, cov khoom siv hluav taws xob rwb thaiv tsev, cable sheath, cov khoom siv ntshav, thiab lwm yam.

1.PVC cov khoom muag muag thiab tawv tawv - siv extruder tuaj yeem nyem rau hauv cov kav dej mos thiab tawv, cables, xov hlau, thiab lwm yam;Nrog lub tshuab txhaj tshuaj molding thiab ntau yam pwm, nws tuaj yeem ua rau hauv cov khau yas, khau khiab, khau khiab, cov khoom ua si, khoom siv txhua hnub thiab tsheb thiab khoom siv hluav taws xob.

2 PVC rigid yeeb nkab thiab profile - txheeb ze rau lwm yam plastics, PVC aging kuj yog zoo heev, muaj feem xyuam rau lub zog thiab toughness, uas tsis muaj nqi, haum rau cov kav dej thiab lwm yam kev siv yeeb nkab, thiab profile profile.

3 PVC zaj duab xis - PVC thiab additives mix, plasticizing, siv peb los yog plaub yob dov mechanism rau hauv ib tug tshwj xeeb thickness ntawm pob tshab los yog xim zaj duab xis, nrog rau txoj kev no ua zaj duab xis, ua calendering zaj duab xis.Kuj tseem tuaj yeem raug txiav, thermal ua cov hnab ntim khoom, raincoats, tablecloths, curtains, inflatable cov khoom ua si thiab lwm yam.Dav pob tshab zaj duab xis tuaj yeem siv rau tsev cog khoom, tsev cog khoom yas thiab yas zaj duab xis.Tom qab bidirectional stretching ntawm zaj duab xis, cov cuab yeej ntawm tshav kub shrinkage, yuav siv tau rau shrink ntim.

4 PVC coated khoom - nrog rau cov substrate ntawm cov tawv nqaij yog PVC tsis meej pem ntawm daim ntaub los yog ntawv, thiab ces nyob rau hauv 100 degrees Celsius saum plasticized.Kuj tseem tuaj yeem yog PVC thiab auxiliary calendering zaj duab xis, thiab tom qab ntawd nias ua ke nrog cov substrate.Cov tawv tawv tsis muaj substrate yog ncaj qha calendered los ntawm lub tshuab calendering rau hauv ib lub thickness ntawm cov ntawv mos, thiab ces nias rau ntawm tus qauv.Cov tawv tawv tuaj yeem siv los ua cov khaub ncaws, hnab, phau ntawv npog, sofas thiab tsheb cushions, thiab tawv hauv pem teb, siv los ua cov khoom siv hauv tsev.

5.PVC ua npuas ncauj - mos PVC sib tov, ntxiv tus nqi ntawm foaming tus neeg sawv cev los ua cov ntaub ntawv, ua npuas ncauj molding rau cov yas ua npuas ncauj, ua npuas ncauj khau khiab, khau khiab, insoles, thiab shockproof buffer ntim khoom.Kuj tuaj yeem siv extruder FOUNDATION rau hauv qhov tsis tshua muaj foaming nyuaj PVC daim ntawv thiab profile, tuaj yeem hloov ntoo sim, yog hom tshiab ntawm cov khoom siv hauv tsev.

6 PVC pob tshab daim ntawv - PVC ntxiv cuam tshuam kev hloov kho thiab stabilizer, tom qab sib tov, plasticizing, calendering thiab ua pob tshab ntawv.Kev siv cov txheej txheem kub tuaj yeem ua rau hauv cov thawv ntim pob tshab los yog siv rau lub tshuab nqus tsev hlwv ntim, yog cov khoom ntim zoo heev thiab cov khoom siv zoo nkauj.

7 PVC tawv phaj thiab phaj - PVC stabilizer, lubricant thiab muab tub lim, tom qab sib tov, nrog extruder tuaj yeem extruded ntau yam caliber ntawm cov yeeb nkab nyuaj, cov yeeb nkab tshwj xeeb, hauv qab, siv los ua cov yeeb nkab, cov yeeb nkab haus, lub tes tsho hlau lossis cov ntaiv tuav.Overlapping kub nias ntawm daim ntawv calendered tuaj yeem ua cov nplooj ntawv nyuaj ntawm ntau yam thicknesses.Lub phaj tuaj yeem txiav rau hauv cov duab uas xav tau, thiab tom qab ntawd siv PVC electrodes nrog cov cua kub vuam rau hauv ntau yam tshuaj tiv thaiv corrosion resistant cia tank, cua ducts thiab ntim.

8.PVC lwm yam - qhov rooj thiab qhov rais yog ua los ntawm cov khoom siv tshwj xeeb zoo li tawv.Hauv qee lub tebchaws tau nrog cov qhov rooj ntoo thiab qhov rais aluminium qhov rais thiab lwm qhov rooj thiab qhov rais lag luam;Imitation ntoo cov ntaub ntawv, tiam steel tsev cov ntaub ntawv (sab qaum teb, seaside);Hollow thawv.

Post lub sij hawm: Aug-08-2022